Medical Logistics

Almost silent, cleanroom-capable, adaptable to any environment. These are the ingredients that help Servus find the ideal recipe for your intralogistics. Autonomous transport robots by Servus can also be used to transport material in the cleanroom as well as in the high-concentration area. The flexible modular assembly kit by Servus lets you fully automate your laboratory.

Patient-oriented management next level:

How Servus Medical Logistics is revolutionizing hospital intralogistics

Servus Medical Logistics: The system for highest demands

The innovative solution for all challenges of modern hospital logistics

The demands on the quality of processes and services in hospitals are constantly evolving. Increasing demands and cost pressures are quickly accumulating. Staff relief, space savings, minimum provisioning times, sustainability, hygiene, flexibility and future viability are just some of the topics on the agenda.

The solutions for this are based on standardization, digitization and automation. Servus Medical Logistics automates internal transport in hospitals and ensures the seamless flow of goods.

At the heart of every Servus system are the intelligent and autonomous transport robots, also called "ARCs" (Autonomous Robotic Carriers).

- Customized solution

- Flexible and scalable

- Implementation in existing buildings

- Process reliability and transparency

The unique logistics kit from Servus

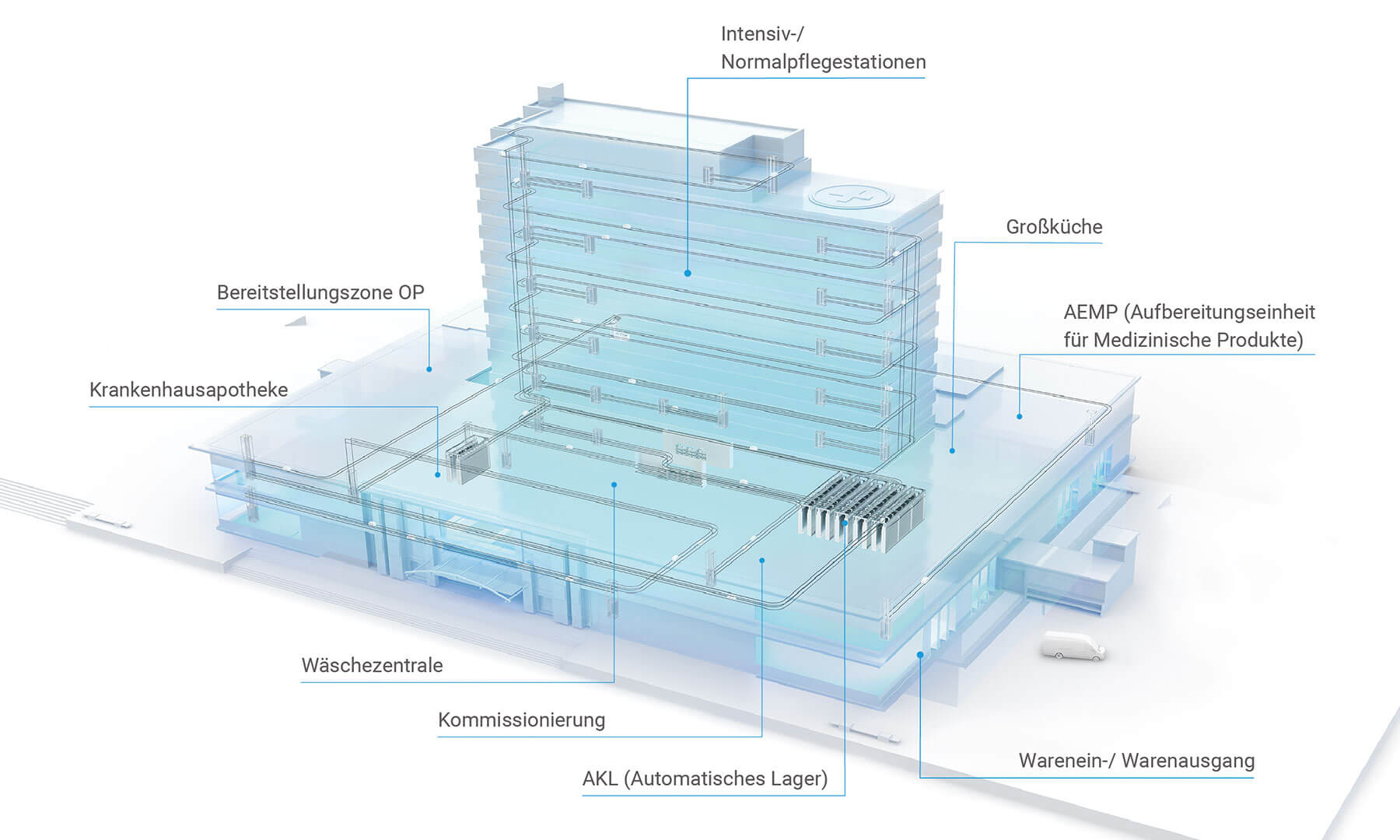

One system for all areas of hospital logistics: from inbound to surgical supply

Full concentration on the essentials

The hospital staff look after the patients' well-being. Servus takes care of the rest.

Ease of use, fast access to all goods, as well as full transparency of all processes and inventories are the hallmarks of the Servus system. This makes it easier for many employees to concentrate on their really important tasks - such as direct contact with patients, ORs, intensive and normal care, etc. Servus takes care of the storage, provision and transport of the required items. The goods arrive just-in-time at the right place. The result: no waiting times and fast response in emergency situations.

MedARC: the expert for hospitals

The MedARC (Medical Autonomous Robotic Carrier) was developed specifically for applications in hospitals. The MedARC picks up transport units at a location and transports them to a specified destination. It is intelligent and has its own power on board. Traveling on a rail system with assistants - such as switches and lifts - it connects all relevant locations throughout the building. The MedARC always knows where it is and knows the shortest route to its destination. The containers or trays with the required goods are managed by the system or stored in the system until they are requested.

Case-related items, such as sterile containers, pre-assorted surgery boxes and consumables, are transported primarily for OR logistics. All required processes can be integrated into one system: OR logistics, commercial kitchen, central laundry, CSSD*, nursing departments, hospital pharmacy, or even inbound and storage. MedARC is a true specialist for every department.

- Easy to use

- Clear access to all goods

- Possibility to request materials on a case-by-case basis

- Cost-efficiently designed processes

But first, a workshop

Servus Intralogistics stands for customized solutions. The foundation for successful projects is laid in a joint workshop. The Servus Lean Logistics experts work out the ideal state in close cooperation with the customer's responsible specialists. In addition to the customer-specific requirements, this ideal state serves as a guide to a future-proof overall solution.

The result of a successful Servus workshop includes a clear material flow diagram, the initial drafts of the processes and plant components, a standardized container concept, and a rough layout of the future plant. The results obtained are then further detailed and the processes precisely coordinated. Basic principles are the avoidance of waste, the sensible use of automation and digitization, and the increase in efficiency in the overall system.

The result: more flexibility, more scalability, more long-term reliability

Convincing Facts

What does Servus transport for you?

- Surgical supplies and instruments

- Sterile items

- Surgical linen and bed linen

- Material requested

- Food

- Lab samples

- Medicines

- Waste

- Blood reserves and blood samples

- and much more

The Servus MedARC

- Speed: up to 4 m/s

- Acceleration: up to 2 m/s

- Material: antibacterial stainless steel and abrasion-resistant plastic

- Gentle handling of transported goods

- Connects workplaces within a hospital (networked medical logistics)

Software

- Easy to use

- Overview of inventories in real time

- Track and Trace

- IT-supported procurement

- Automatic material request

- Supplier connection

- Easy integration into existing software possible

- Voice control

Key features

- Dynamic order prioritization

- Fastest material request

- Process and fail-safe system

- Separation of flows of people and goods

- Availability 24/7

- Case-by-case costing

- Scalable and flexible

- Service and support

All info for download

Here you can download the brochure as a PDF!