Initial Situation

Customer Benefit

- Hamilton is establishing itself in the field of clinical diagnostic research laboratories as well as in the food, pharmaceutical and biotechnology industries.

- New building required the redesign of the operative logistics processes.

- Desire for maximum efficiency thanks to newly introduced lean management.

- Looking for a link between the various assembly and production areas, which span several floors.

- Fully automated and interface-free networking between incoming and outgoing goods, order picking, production areas and ASRS.

- Material-friendly, efficient and reliable product transport.

- Planned increase in production even exceeded.

- Simultaneous handling of several work steps.

- Flexibility for the future thanks to the scalability of the system.

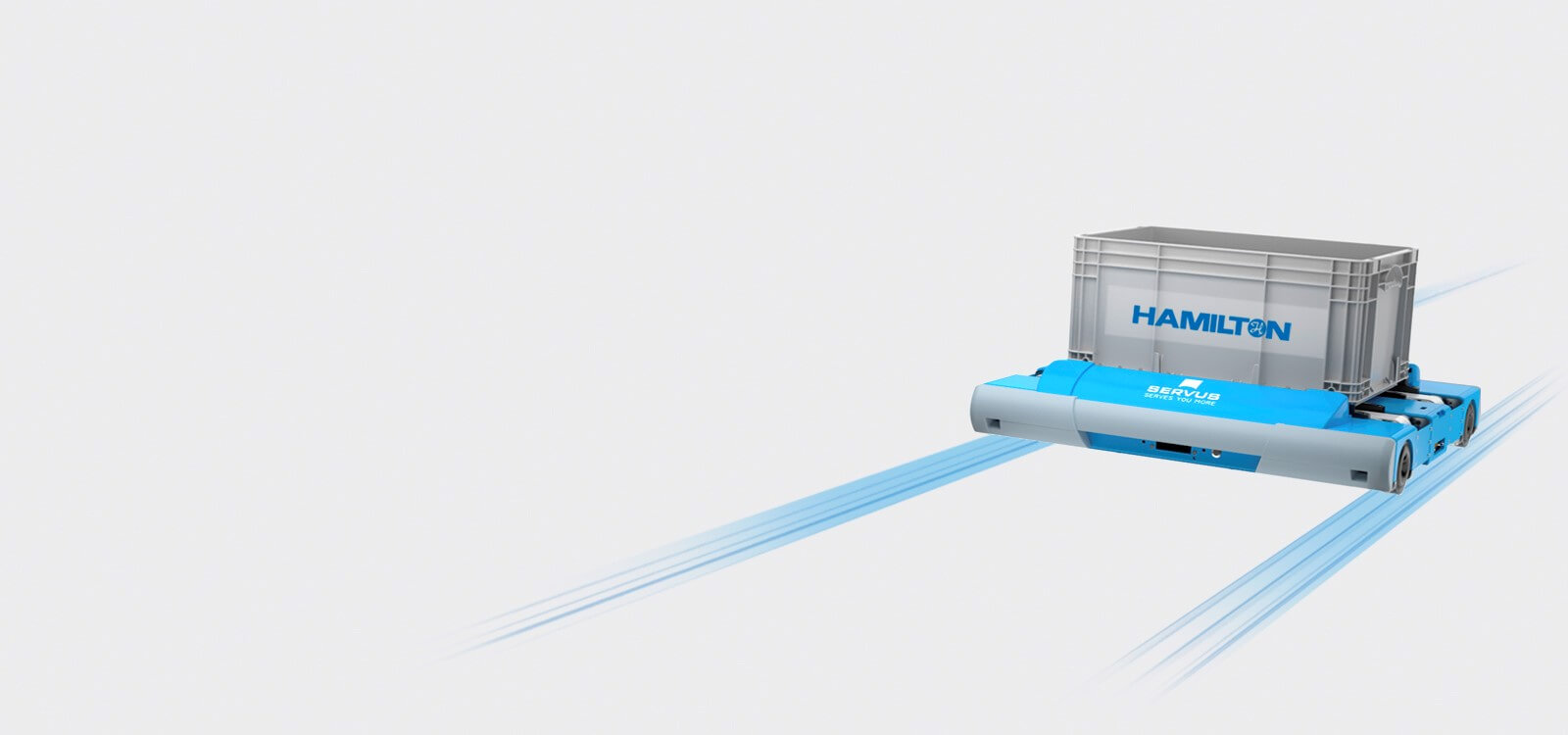

Servus in Action at Hamilton

Hamilton stands for technology, quality and precision in various markets of the food, pharmaceutical and biotechnology industries. The company used a building extension to efficiently redesign its entire logistics. Servus developed a concept that enables Hamilton's uncompromising quality with maximum efficiency in the entire production and transport logistics. The production areas are approached in a ring-shaped loop route and ensure optimum material supply.

Hamilton

Chemical engineer Clark Hamilton developed the first microlitre syringe for chromatography in 1947. In the meantime, syringes, robotic systems and dilution devices, as well as special sensors are also part of the company's product portfolio. Hamilton excels in high-precision dosing and measuring of liquids and gases in various markets. Today Hamilton is one of the world's leading suppliers of ventilators.

We were able to accelerate our entire intralogistics processes.