Initial Situation

- Long transport routes between warehouse and production

- Manual transport used too often

- Automation of assembly line supply system desired to ensure just-in-time provisioning of the picked goods to the assembly lines

- Decoupling of picking activities from the milk run cycle

Customer Benefits

- Automated transport between incoming goods, warehouse and assembly

- Safer, more flexible and more efficient process due to decoupling of picking and assembly

- Optimised use of picking

- Ensuring the just-in-time material provisioning

- Reducing work-in-progress stock, i.e. as little material as possible in the production, and much as needed

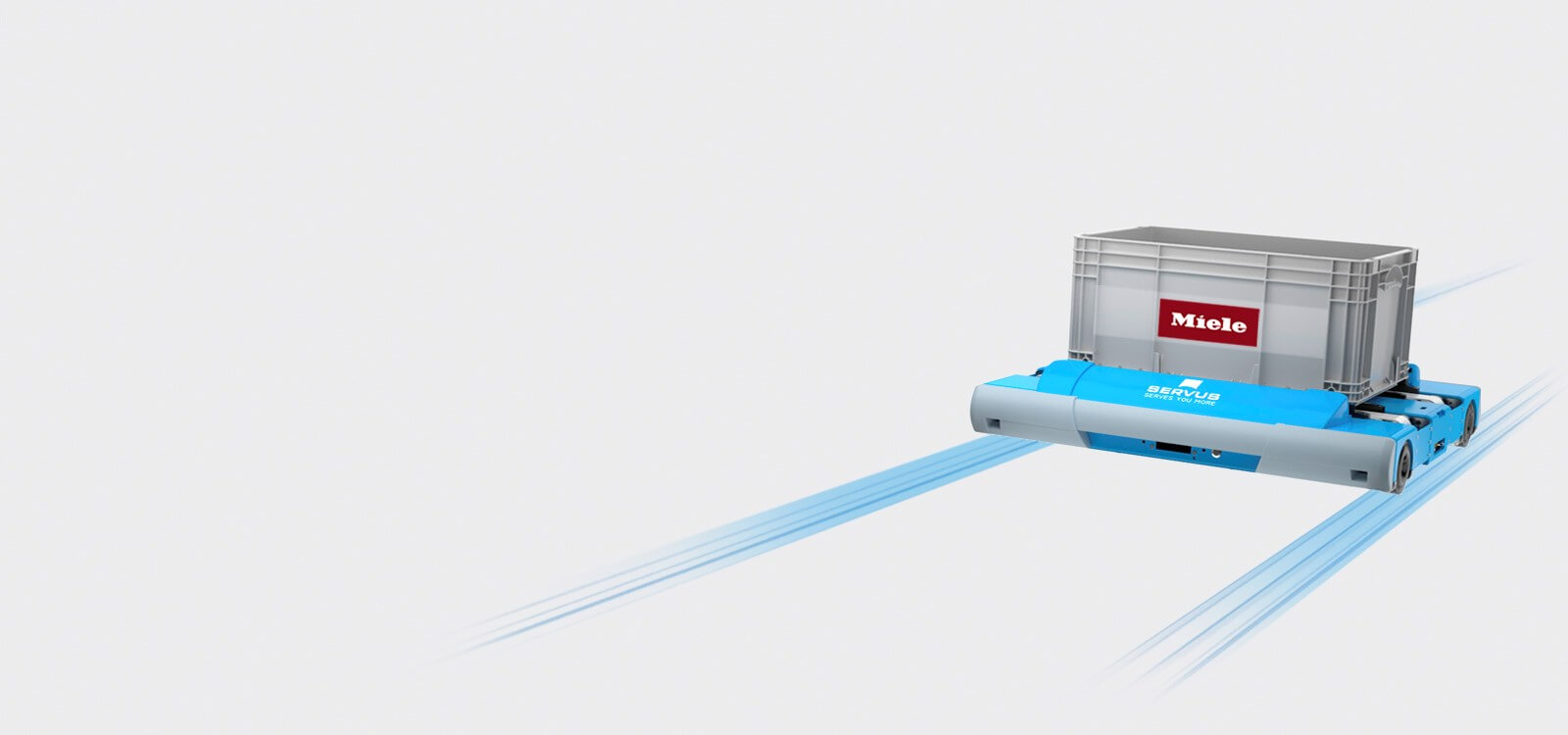

Servus in Action at Miele

Caption: Miele started to use Servus to provision its assembly lines in 2014. 4500 washing machines are made every day. The materials, small parts and components required for this are buffered by the Servus system in an AKL and supplied at the right time and in the right volumes. The system is constantly adapted and developed to reflect changing requirements and continuously increase the efficiency of the production logistics.

More information on the Servus system at Miele in Gütersloh can be found in the Miele Case Study.

Miele & Cie. KG

Since it was founded in 1899, Miele has been an independent family-operated business which feels equally committed to its owners, employees, customers, suppliers, the environment and society as a whole. Miele produces electrical appliances for households and industry. “Better and better”, the founders wrote on their first products. Like a common thread, these words run through the Miele success story that started over a hundred years ago.

In the 2016/2017 financial year, ending on 30 June 2017, the company generated a turnover of 3.93 billion euros.

A warehouse with RGB would have cost us a lot more and by no means met our flexibility requirements. With a view to our throughput volumes and transport routes, we need a system that ensures maximum flexibility, which is why the scalability aspect is of great importance. The Servus system can easily be adjusted to match capacity levels. If there is less work to do, we take some of the ARCs out of traffic operations and park them elsewhere. However, if we need more ARCs, they can be easily integrated – register with the system, put them on the track and off they go.”

Markus Kahlert,