Effective. Flexible. Universal.

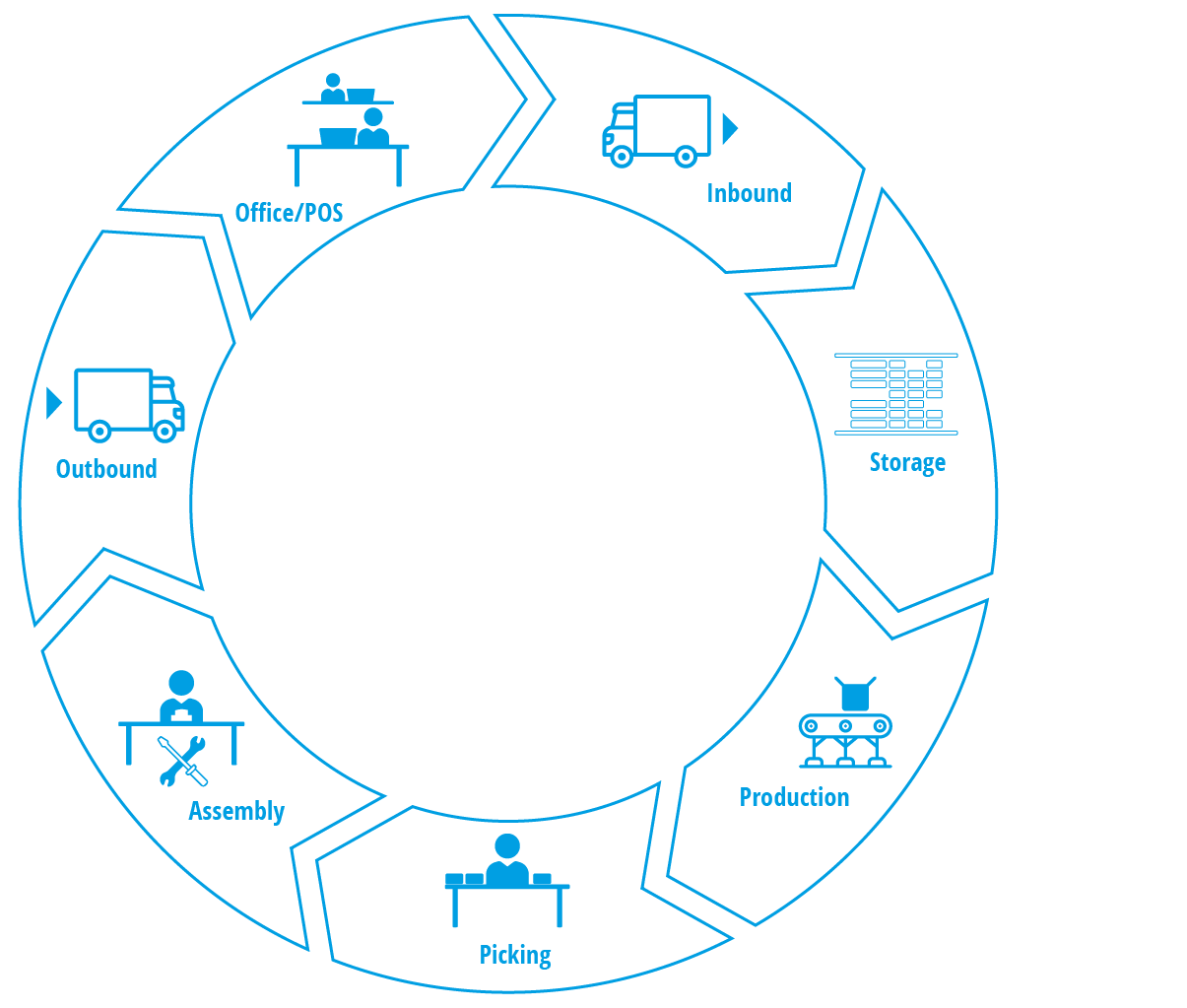

Design your individual intralogistics solution to suit your needs and ensure your success in the long term. Thanks to the Servus logistics modular assembly kit, Industry 4.0 is no longer just a buzzword. Servus combines the principles of “lean culture” with the benefits of Industry 4.0 in your company. The system ensures a high level of process assurance, is easily scalable and allows for optimum cooperation between logistics and production. An optimised material flow reduces unnecessary interim storage and thus frees up your “working capital”.

The Servus Logistics Modular Assembly Kit.

From the components of the Servus logistic modular assembly kit, we can develop tailor-made solutions for you to optimise and automate the material flow along your entire value chain.

- Servus ARC3 transport robot

- Automated Storage and Retrieval System (ASRS)

- Route system and assistance systems

- Load Handling Device

- Software & communication

- Connections and stations

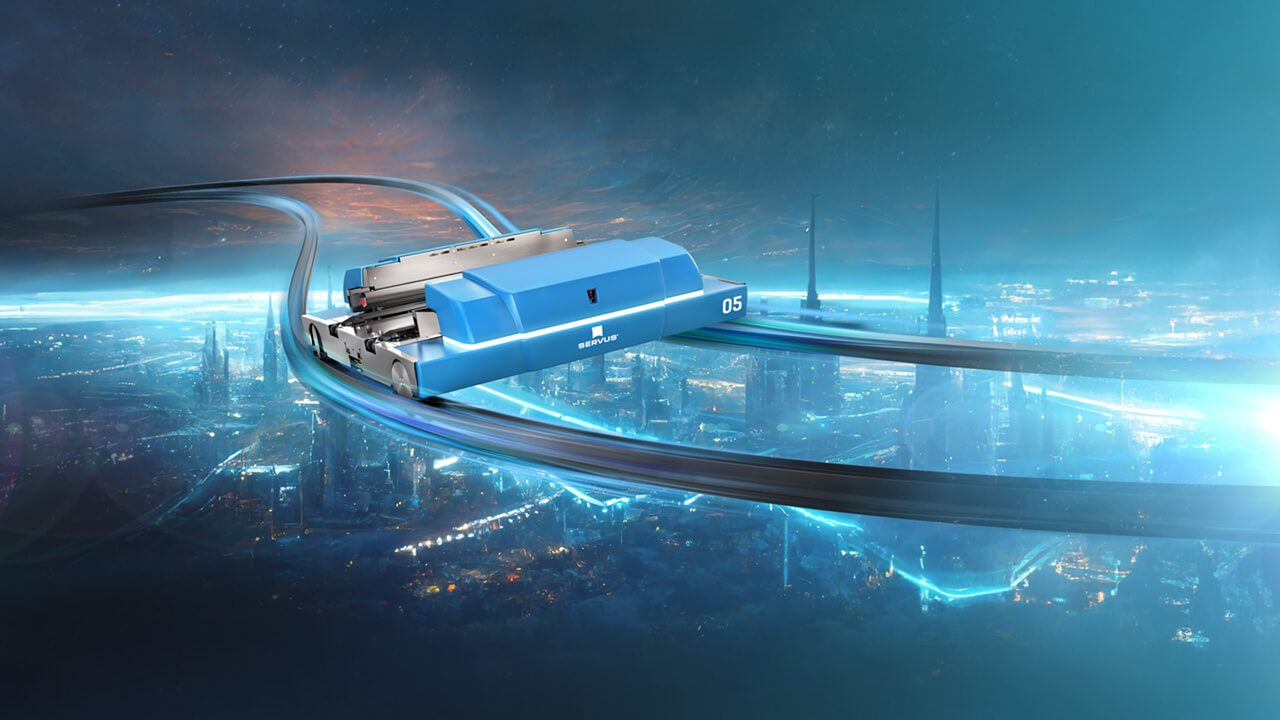

The new ARC5: around the world for 80 euros

More power. More speed. More efficiency.

Welcome to the 5th generation to our transport robots. The new Servus ARC5 - the world's most energy-efficient transport robot for the entire value chain. With numerous features, the ARC5 was developed with a clear goal: Efficiency, safety and competitiveness for our customers.

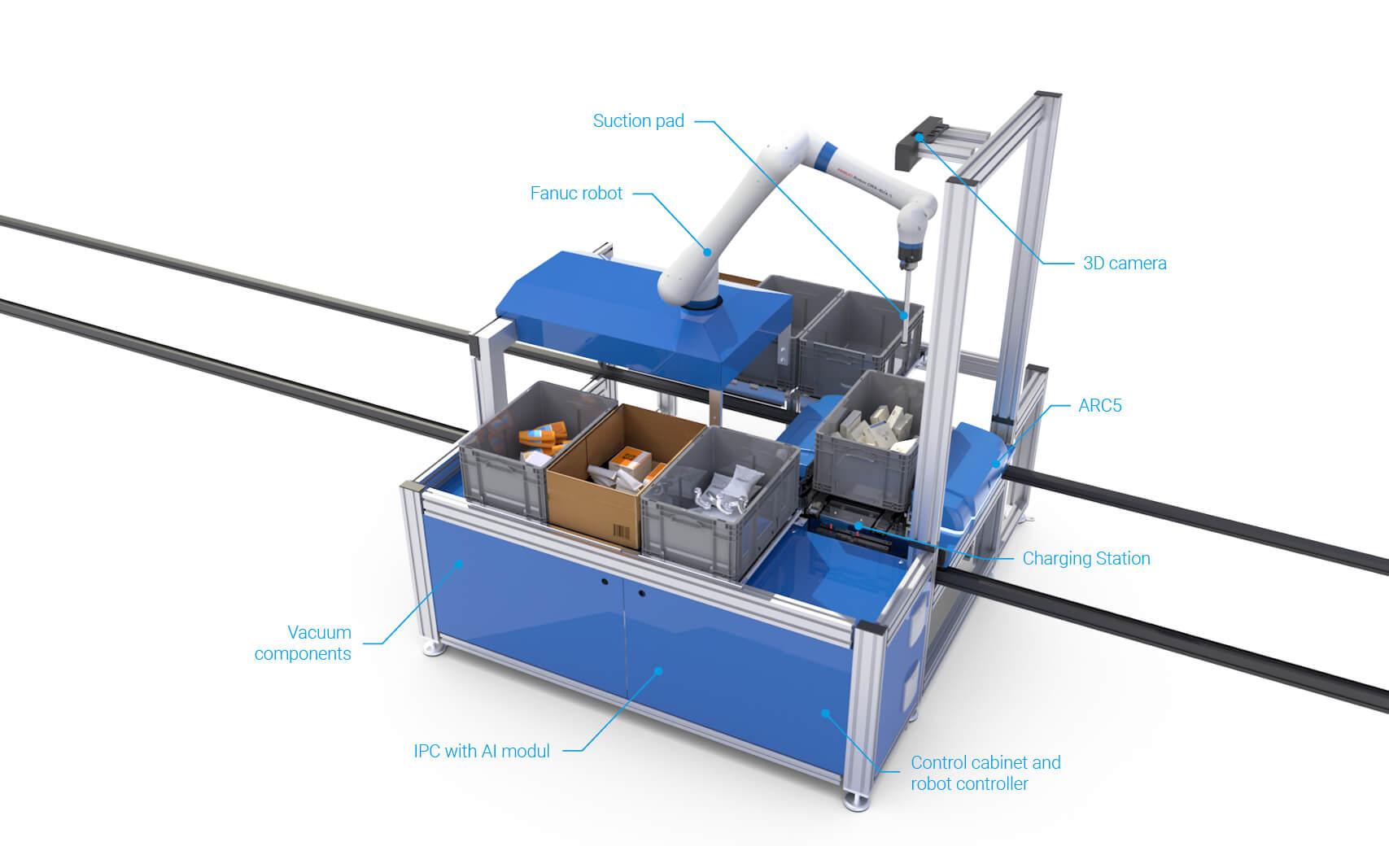

Servus PickStation: easy and efficient

In the hybrid picking solution, the Servus PickStation works 24/7 on picking orders of all items. With a clear goal: efficiency, simplicity and time savings in picking. Contact us for more information.

Automated Storage and Retrieval System (ASRS)

Since the Servus transport robots travel out of the warehouse, the Servus ASRS is fully integrated with the flow process. Depending on the requirements, a Servus ASRS is suitable for slow movers or highly dynamic storage and removal, for single or double-depth storage, and for central or localised storage.

The combination of exceptional storage density and the highest storage capacity utilisation with direct access ensures maximum flexibility with low space requirements. Capacity and performance can be increased and adjusted at any time by adding more swarm robots.

Track and Assistants System

The guide elements are simple carrier sections without wiring and sliding contacts. The allows for a flexible route guidance and ideal adaptation to the current or a new infrastructure. The Servus track is predominantly overhead. This frees up valuable space for production purposes.

Assistance systems such as lifts or switches, are integrated into the route system and enable easy integration of local storage locations, assembly or picking stations on different floors and in different buildings. Lifts and switches help Servus during its journey. This is why we call them assistance systems. The Servus ARC communicates directly with the lifts and switches without a central control. This keeps the system scalable, fast and flexible.

Load Handling Device

Depending on the requirements, different load handling devices are integrated into Servus ARC3 for automatic loading and unloading of individual goods. The various load handling devices guarantee gentle and efficient handling of boxes, cartons, trays, bulk materials, or customer-specific workpieces at top speeds.

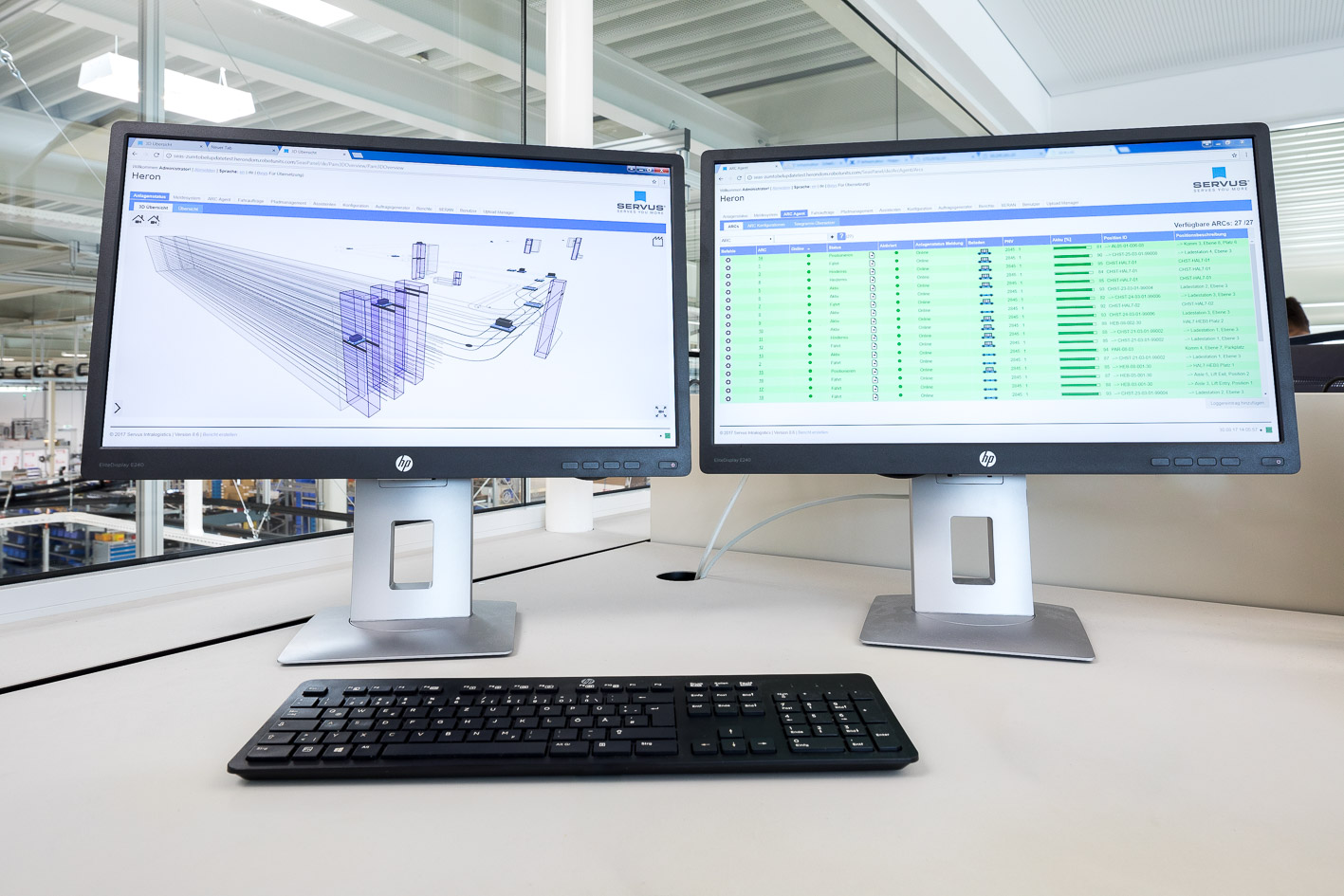

Software & Communication

The Servus system does not require a central control and works in a similar way to a taxi company. The ARC3 (taxi) receives its orders via various options. One of these options is the taxi centre. The taxi centre is directly connected to the Warehouse Management System (WMS), either to WMS by Servus or to any storage management system (Microsoft, SAP, etc.). However, with the WMS from Servus, the processes can be synchronised and efficiency increases in a superior way.

Connections and Stations

Individual system components, such as storage and removal stations, stations, assembly and picking stations or breathing buffers make the delivery and collection of goods possible at any location in the company. Due to Just-in-Time delivery, work-in-progress stock can be reduced and unnecessary storage between processes avoided.

Whether fully automated or manual workstations – you can connect all value-adding processes directly to your logistics.